In an era of rapid digital transformation, traditional manufacturing is undergoing a significant evolution. At the forefront of this change are rugged tablets, like those offered by Rugstorm, which are fundamentally reshaping how factories operate, from the shop floor to the executive suite. These purpose-built devices are not just replacing clipboards and paper; they are empowering a more efficient, agile, and data-driven manufacturing environment.

The Limitations of Traditional Manufacturing and the Need for Change

For decades, manufacturing processes relied heavily on manual data entry, paper-based instructions, and a relatively static flow of information. This approach, while proven, presented numerous challenges:

- Inefficiency: Manual data collection is time-consuming and prone to errors.

- Lack of Real-time Visibility: Decisions were often based on outdated information, leading to delays and missed opportunities.

- Limited Collaboration: Communication breakdowns between different departments and shifts were common.

- Harsh Environments: Standard consumer-grade devices simply couldn’t withstand the dust, vibration, extreme temperatures, and potential drops inherent in factory settings.

- Compliance and Traceability Issues: Maintaining accurate records for audits and product traceability was a constant struggle.

The Rugged Tablet Revolution: Key Impacts on Manufacturing

Rugged tablets are specifically designed to thrive in challenging industrial environments, offering a robust and reliable platform for digitalizing manufacturing operations. Here’s how they are driving significant change:

1. Enhanced Shop Floor Efficiency and Data Accuracy

- Digital Work Instructions and Checklists: Operators can access interactive work instructions, assembly guides, and digital checklists directly on their rugged tablets, reducing errors and ensuring consistency.

- Real-time Data Capture: Instead of manual input, data can be collected instantly via barcode scanners, RFID readers, and integrated sensors, providing immediate insights into production status, machine performance, and quality control.

- Elimination of Paperwork: Rugged tablets reduce reliance on paper forms, minimizing clutter, saving costs, and streamlining information flow.

2. Improved Quality Control and Compliance

- Instant Defect Reporting: Workers can immediately log defects, take photos, and annotate issues on the tablet, facilitating faster corrective actions and reducing scrap.

- Digital Inspection Logs: Automated logging of inspection data ensures comprehensive records for quality assurance and compliance audits.

- Traceability and Genealogy: Rugged tablets facilitate the tracking of components and products throughout the manufacturing process, providing a robust audit trail for regulatory compliance and recall management.

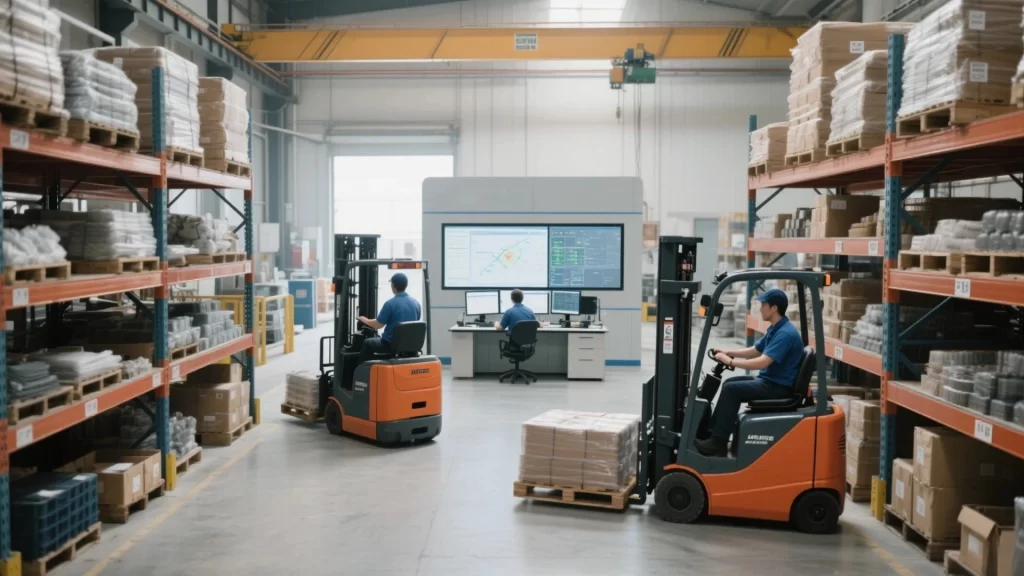

3. Streamlined Inventory and Warehouse Management

- Real-time Inventory Updates: Integration with warehouse management systems allows for accurate, real-time tracking of raw materials, work-in-progress, and finished goods, optimizing inventory levels and reducing stockouts.

- Efficient Picking and Packing: Guided workflows on rugged tablets can direct workers to the correct locations and ensure accurate order fulfillment.

- Asset Tracking: Tablets can be used to track the location and status of tools, equipment, and other valuable assets on the factory floor.

4. Predictive Maintenance and Machine Monitoring

- Direct Access to Machine Diagnostics: Technicians can use rugged tablets to access real-time data from connected machinery, monitor performance, and diagnose issues on the spot.

- Maintenance Workflows: Tablets can guide technicians through maintenance procedures, display repair manuals, and log completed tasks, improving efficiency and reducing downtime.

- Integration with IoT Sensors: When paired with IoT sensors, rugged tablets become a powerful tool for predictive maintenance, alerting operators to potential equipment failures before they occur.

5. Enhanced Communication and Collaboration

- Instant Communication: Workers can communicate with supervisors, engineers, and other departments directly from their tablets via messaging apps or video calls, fostering better collaboration.

- Access to Centralized Information: Critical documents, schematics, and best practices can be accessed on demand, ensuring everyone has the latest information.

- Remote Assistance: Experts can provide remote guidance and troubleshooting by viewing what a worker sees through the tablet’s camera.

Why Rugstorm Rugged Tablets Are Ideal for Manufacturing

Rugstorm rugged tablets are specifically engineered to meet the demanding requirements of industrial environments. Their key features include:

- Unmatched Durability: Designed to withstand drops, vibrations, dust, water, and extreme temperatures, ensuring reliable performance in harsh factory conditions.

- Long Battery Life: Extended battery life supports full shifts without interruption, crucial for continuous operations.

- ** sunlight-readable Displays:** Clear visibility even in bright factory lighting or outdoor environments.

- Versatile Connectivity: Wi-Fi, Bluetooth, 4G/5G, and GPS ensure seamless communication and data transfer.

- Integrated Peripherals: Optional barcode scanners, RFID readers, and other modules provide comprehensive data capture capabilities.

- Customizable Solutions: Rugstorm offers a range of sizes, operating systems, and configurations to meet specific manufacturing needs.

The Future of Manufacturing is Rugged and Connected

The adoption of rugged tablets is not just a trend; it’s a fundamental shift towards a more intelligent and responsive manufacturing future. By providing robust, reliable, and connected tools to the workforce, companies like Rugstorm are empowering manufacturers to:

- Increase Productivity and Throughput: Streamlined workflows and real-time data lead to higher output.

- Reduce Operational Costs: Minimizing errors, downtime, and paperwork translates to significant savings.

- Improve Product Quality: Better control and immediate feedback mechanisms ensure higher quality products.

- Enhance Worker Safety: Digital workflows and real-time alerts can contribute to a safer working environment.

- Drive Innovation: The availability of real-time data fosters continuous improvement and innovation across the entire value chain.

Traditional manufacturing is no longer about static assembly lines; it’s about dynamic, data-driven, and highly optimized processes. Rugged tablets are the essential tools that make this transformation possible, paving the way for the smart factories of tomorrow.